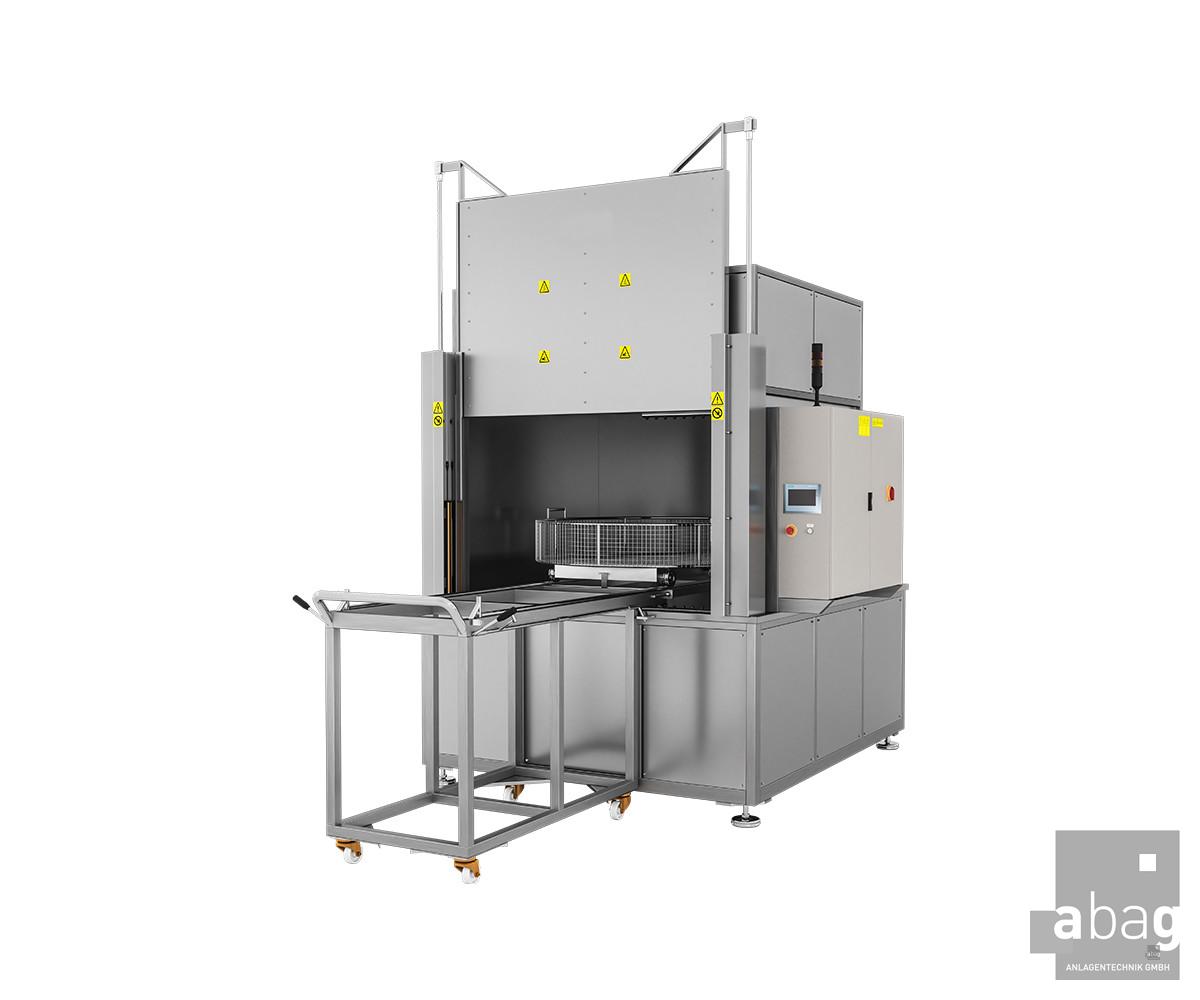

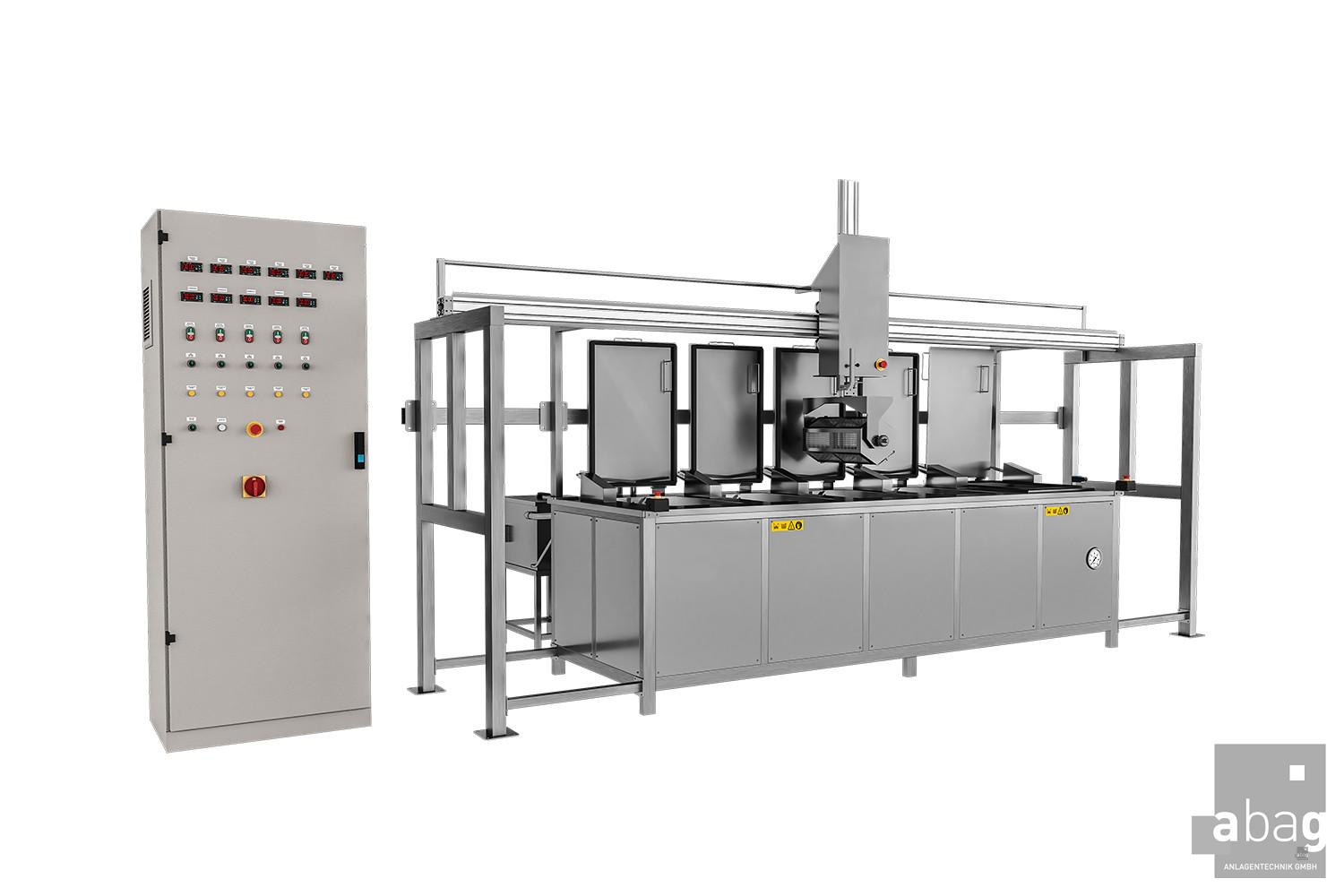

Depending on the cleaning requirements, the UR-M series offers systems with two, three, four or five cleaning tanks. Plant and tub sizes are determined according to the component size. The machine structure is designed according to customer needs and cleaning requirements. The most important stages in partial cleaning are the pre-cleaning, ultrasonic cleaning, rinsing, passivation and drying processes.

Pre-cleaning

For the treatment of extremely dirty components. Pre-cleaning means that the ultrasonic bath is less contaminated with dirt.

Ultrasonic cleaning

Complete removal of dirt on the components by ultrasonic waves. Well suited for hard-to-reach places.

Flushing

Rinsing off remaining alkaline substances and chemicals.

Passivation

Passivation creates a protective layer that makes the component more resistant to corrosion.

Drying

Completely dries the component in the last tub.

Options

Oil skimmers, circulation, filtration, air blast, parts transport or pneumatic covers are just a few options that can be installed in these machines depending on the cleaning requirements.