Cleaning Technology

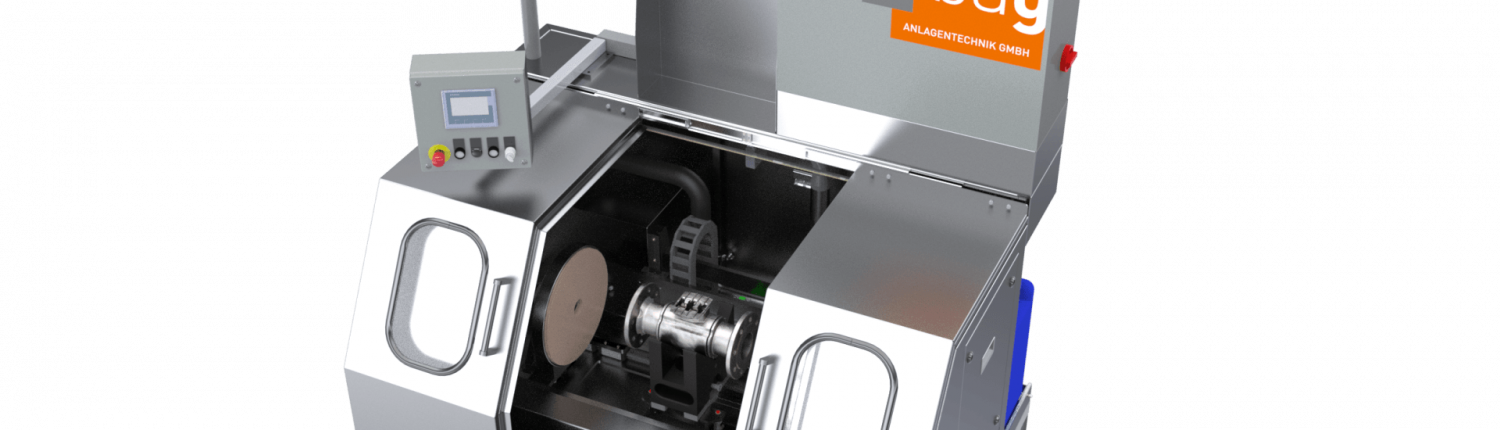

Dip bath cleaning

Loose impurities from machining processes, such as cooling lubricant, dust, chips and scaling, are solved by completely submerging them. A suitable cleaning medium is added to the water bath. In order to dissolve oils, fats and waxes, the bath is heated.

Optionally, a mechanical cleaning effect can be supplemented by brushes, nozzles or ultrasound.

Spray cleaning

The workpiece is sprayed with the cleaning liquid from all sides. The intensity is set via the volume flow and pressure. Cavities and bores are specifically cleaned by movable lances.

The dirty water is collected, filtered in several stages and reused for cleaning in the circulation system.

Ultrasonic cleaning

If ultrasound is applied to the cleaning bath during the immersion bath process, firmly attached impurities can also be loosened. With appropriate dimensions, the cleaning performance corresponds to a high-pressure cleaning. Even the smallest particles in angled corners are reached by the sound waves.

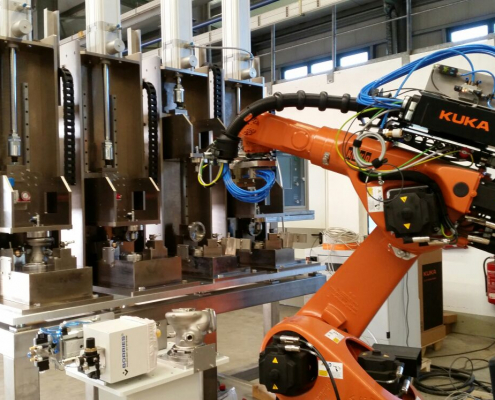

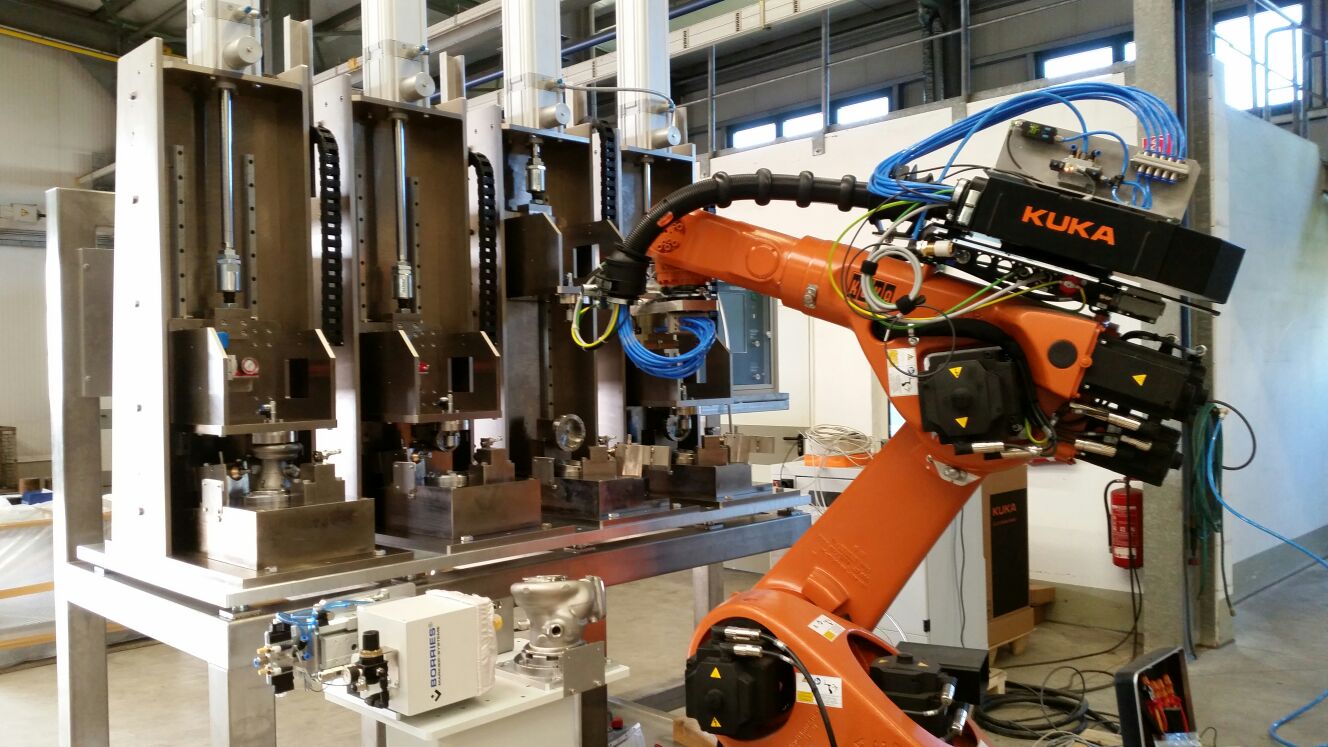

Brush cleaning / deburring

During the mechanical processing of almost all technical materials, chips and burrs appear on the edges. If these are solved in later use, the damage is preprogrammed. The edges can be reworked with brushes and jammed chips can be loosened. Mechanical cleaning of surfaces is also possible.

High pressure deburring

Successful under high pressure!

As an alternative to burr deburring, chips and burrs can be removed by the impulse of a water tool. Depending on the material and the formation of the burr, the pressure must be adjusted. Applications are grooves and borings in pistons with subsequent cleaning. Turbine housings are usually inspected 100% visually for pinch chips.

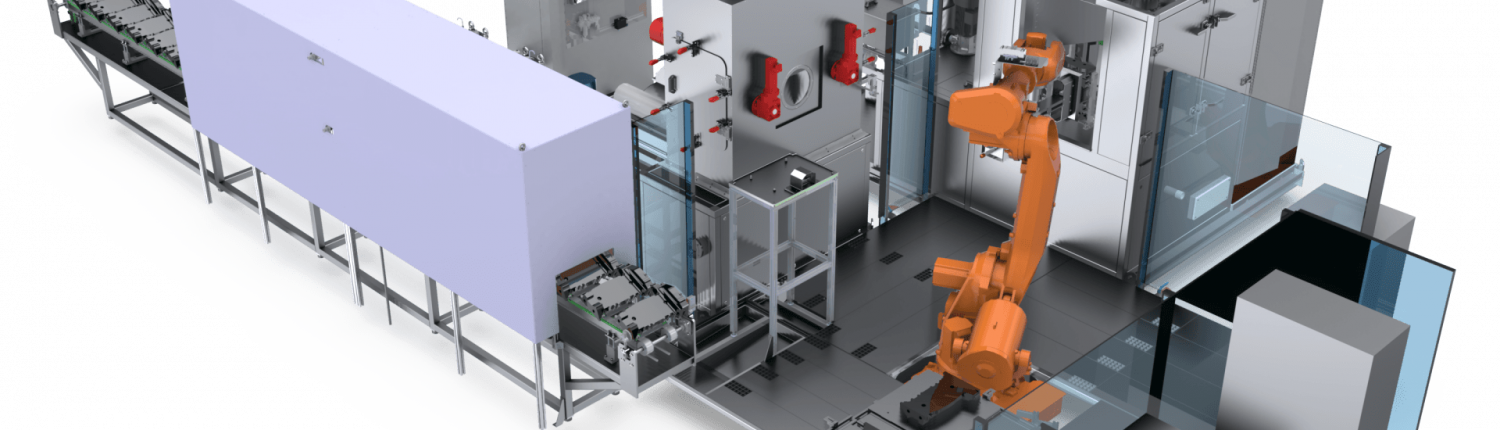

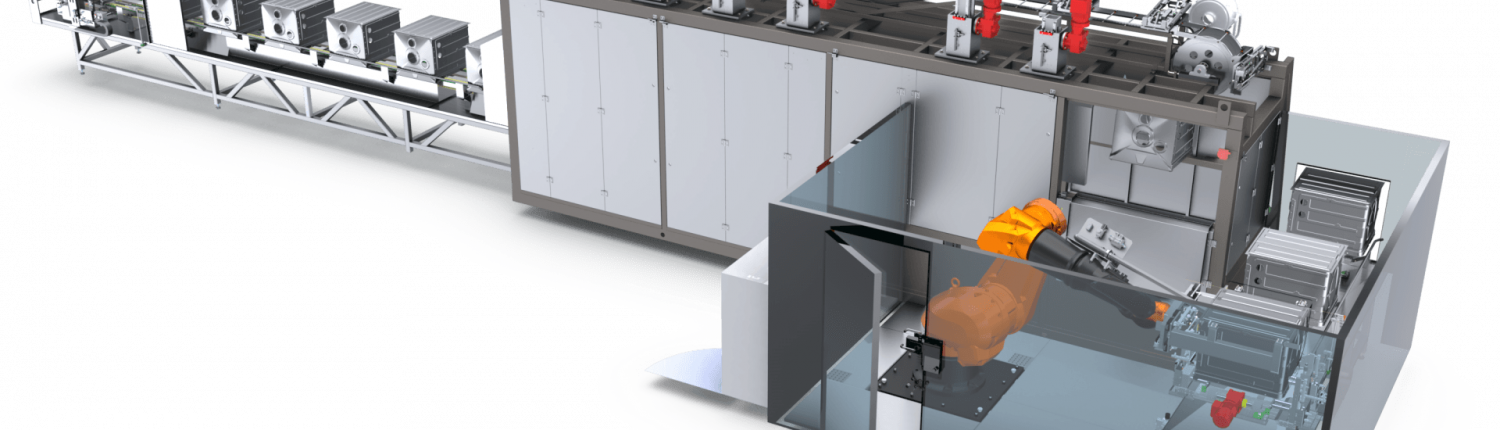

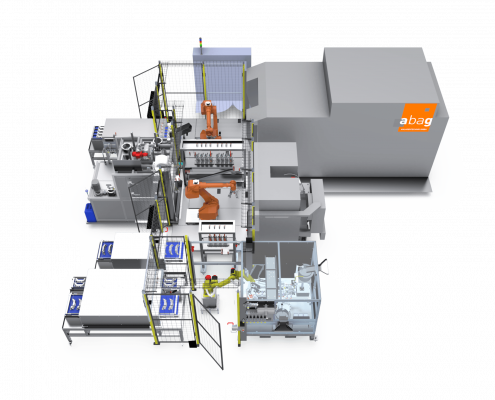

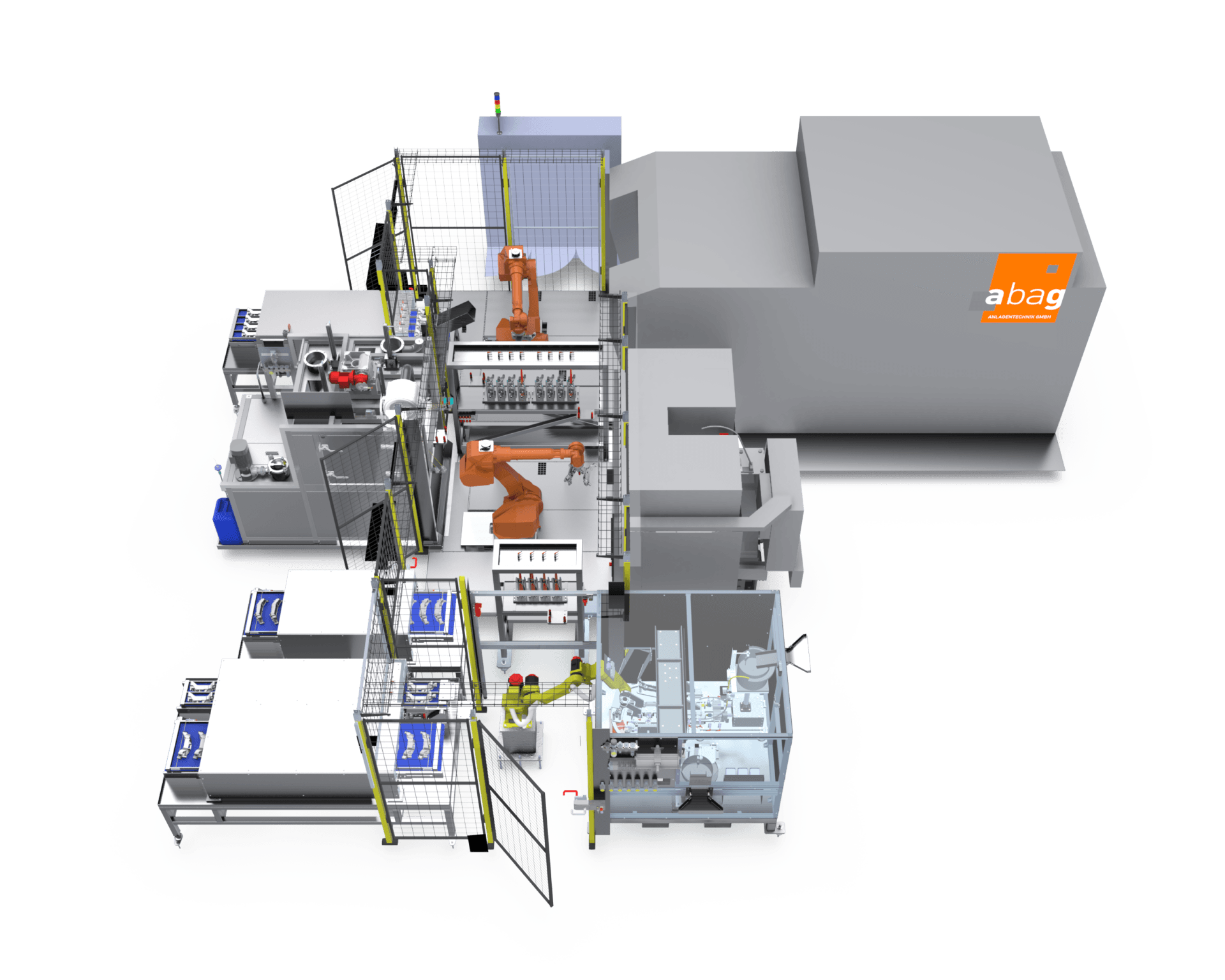

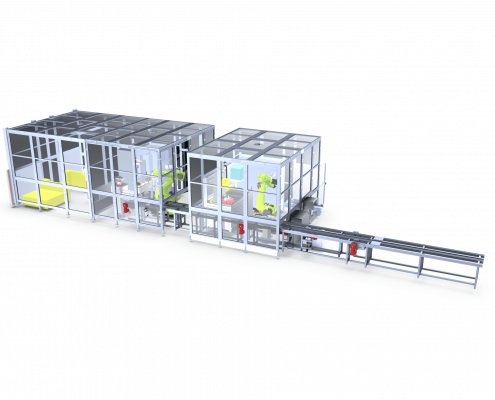

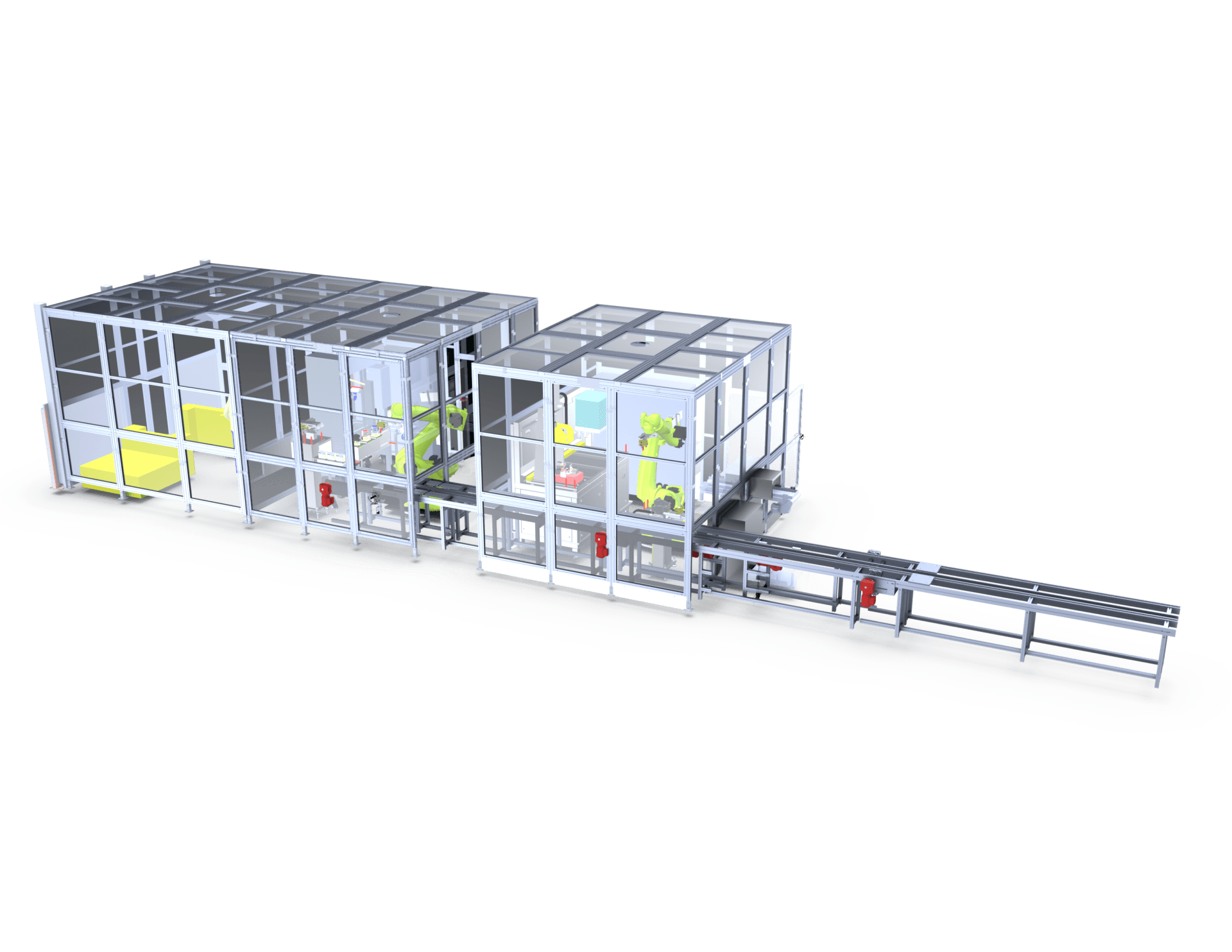

Our special machines are adapted to your components and their cleanliness specifications from chip-free to purewe design exactly the system you need.

We would be happy to clarify what requirements you have in a non-binding discussion, after which our work begins with the design of your cleaning system. Regardless of whether it is a rotary cycle, immersion or continuous cleaning system.

You don’t need a special machine? Then take a look at our portfolio of Standard cleaning systems.